Worried about invisible killer lurking in your Burnaby home through everyday appliances? Let’s dive into detecting deadly carbon monoxide leaks before they turn fatal and keep your family breathing safely. Picture this: you’re cozied up in your Burnaby home on a rainy Vancouver evening, furnace humming quietly, gas stove warming up dinner, and everything feels perfectly safe. But here’s the scary truth I learned after years in the appliance repair game – carbon monoxide could be silently building up around you right now, and you’d have absolutely no idea until it’s too late. This invisible, odorless gas kills approximately 400 people annually across North America, and most of these tragedies happen because homeowners simply didn’t know what to look for. As someone who’s seen way too many close calls in the Vancouver area, I’m breaking down everything you need to know about detecting CO from your home appliances. From that innocent-looking gas stove that might be leaking even when it’s turned off, to your trusty furnace that could develop a cracked heat exchanger without warning, every fuel-burning appliance in your home has the potential to become dangerous. The good news? With the right knowledge and detection strategies, you can catch these issues before they become life-threatening emergencies. We’re going to cover professional detection methods, strategic detector placement that actually works in Vancouver’s unique climate, and those subtle warning signs that most homeowners miss completely. Plus, I’ll share some insider tips about when you absolutely need to call in the pros versus what you can handle yourself.

Key Outtakes

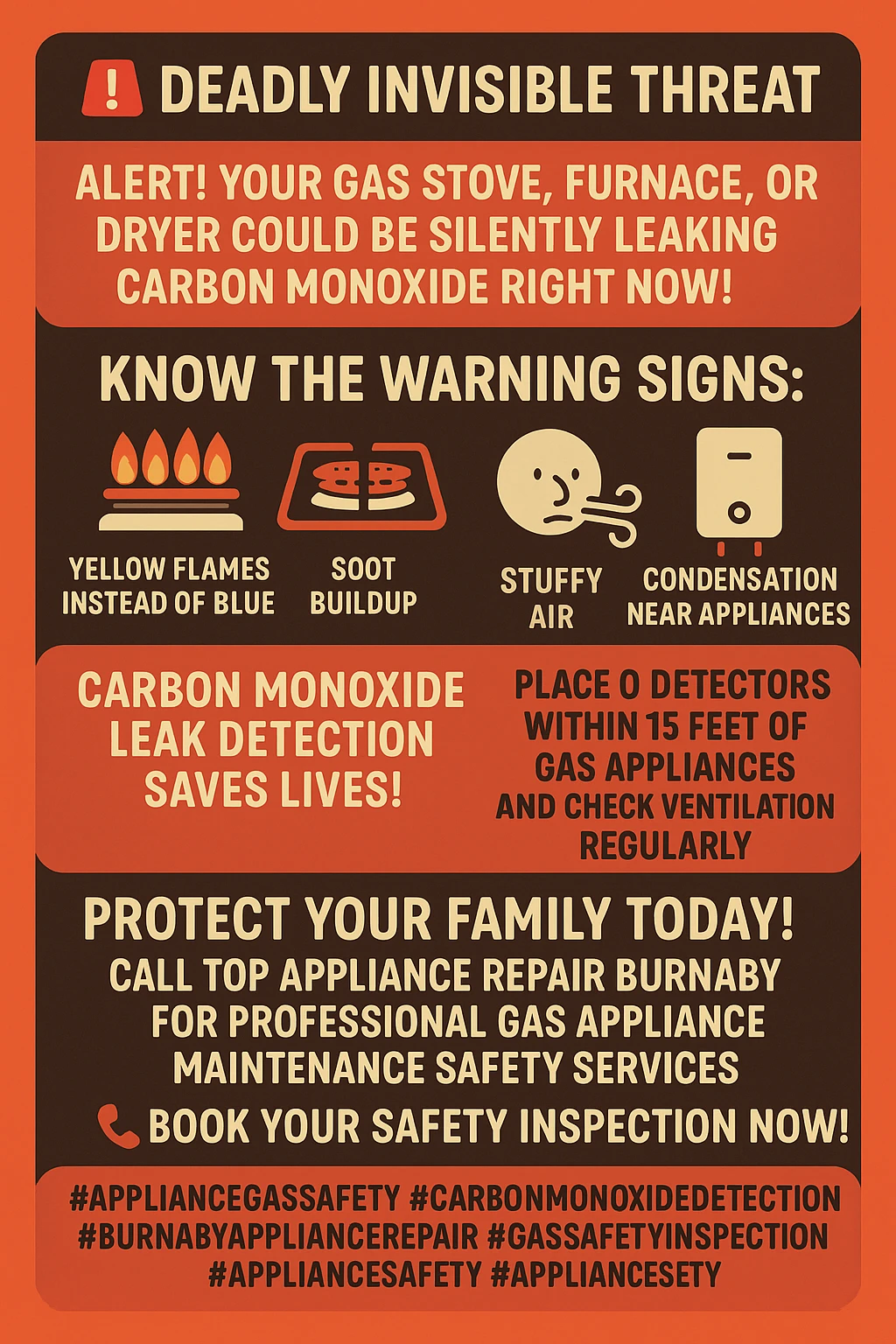

- Carbon monoxide from faulty appliances kills approximately 400 people annually in North America, making early detection systems essential for home safety

- Gas appliances leak methane and toxic compounds even when turned off, with over 75% of emissions occurring during non-use periods

- Professional safety inspections can identify CO risks before they become fatal, particularly crucial for Vancouver area homes with attached garages

- Proper detector placement within 15 feet of gas appliances significantly improves early warning capabilities while avoiding false alarms

- Regular maintenance and immediate response to warning signs can prevent 80% of appliance-related carbon monoxide incidents

Understanding Carbon Monoxide Risks from Home Appliances in Burnaby

Here’s what really gets me fired up about this topic – carbon monoxide is literally everywhere in our homes, yet most people treat it like some distant threat that only happens to “other people.” But when you dig into the numbers, it becomes crystal clear why we need to take this seriously. The CDC estimates that approximately 400 people die from unintentional carbon monoxide exposure every year in the United States, and here in Canada, we’re seeing similar patterns that should make every homeowner pay attention. What makes this particularly sneaky is how CO forms in the first place. Every single time any fuel burns incompletely – whether it’s natural gas in your furnace, propane in your stove, or even gasoline in your car parked in an attached garage – carbon monoxide gets produced. It’s not like your appliances are broken or defective; this is just basic chemistry happening in your home every single day. The difference between safe operation and dangerous levels comes down to proper ventilation, regular maintenance, and early detection. Now here’s something that totally blew my mind when I first learned about it: Stanford University conducted a study analyzing 53 California homes and found that gas stoves leak methane from almost every single unit. But get this – more than three-quarters of those emissions were happening when the stoves were completely turned off! This means your “safe” appliances are potentially creating issues even when you’re not actively using them. For us here in Burnaby and the greater Vancouver area, we’ve got some unique challenges that make CO detection even more critical. Our high humidity levels can actually affect how sensitive CO detectors are, which means we need to be extra strategic about placement. I always tell my clients to keep detectors at least 10 feet away from bathrooms or anywhere with humidifiers, because moisture can throw off the readings and give you false confidence when you should be concerned. Winter conditions create another layer of complexity that most generic safety advice doesn’t address. We get enough snow and ice here that appliance vents can become blocked, and when that happens, CO buildup becomes a serious risk fast. I’ve responded to calls where families were getting sick and couldn’t figure out why, only to discover their furnace vent was completely packed with snow, forcing combustion gases back into the house.

Recognizing Critical Warning Signs of Appliance Gas Leaks

Learning to spot the early warning signs of potential CO problems has literally saved lives in my experience, and it starts with understanding what normal appliance operation should look like versus what screams “danger ahead.” Most homeowners walk past critical warning signs every single day without realizing their appliances are basically sending out SOS signals. The most obvious visual indicator that something’s wrong is flame color, and this is where I see people make dangerous assumptions all the time. Your gas appliances should produce crisp, blue flames when they’re operating properly. If you’re seeing yellow or orange flames instead, that’s your appliance telling you it’s not getting enough air for complete combustion, which means carbon monoxide is almost certainly being produced. I’ve seen too many people dismiss this as “normal” or think it just means their appliance is getting older, but abnormal flames are never something to ignore. Heavy condensation on windows in rooms with gas appliances is another red flag that most people miss completely. When appliances aren’t venting properly, you’ll start seeing excessive moisture on windows and walls near those units. This isn’t just about humidity – it’s often the first sign that combustion gases aren’t going where they’re supposed to go. If you’re noticing this pattern, especially in winter when your heating system is working harder, it’s time to investigate immediately. Soot or staining around appliances is like finding smoke after a fire – it’s visual proof that combustion problems are happening. This black or dark residue doesn’t just appear randomly; it forms when fuel isn’t burning cleanly, and where there’s incomplete combustion, there’s carbon monoxide production. I always tell homeowners to think of soot as appliance acne – it’s showing you that something unhealthy is going on inside. On the auditory side, hissing sounds near gas lines or appliances indicate potential leaks that require immediate attention. This isn’t the normal operational sounds your appliances make during startup or shutdown; this is the sound of gas escaping where it shouldn’t be. Trust your ears on this one – if something sounds different or unusual, don’t convince yourself it’s probably nothing. The distinctive “rotten egg” smell of natural gas signals a completely different but equally serious emergency. Natural gas companies add that odorant specifically so you can detect leaks, and if you’re smelling it consistently near appliances, you’ve got a leak that needs professional attention right now. Don’t light matches, don’t flip electrical switches, and definitely don’t try to “find” the leak yourself with flames. But here’s what’s really insidious about carbon monoxide – by the time you’re experiencing physical symptoms, you’re already in danger. Early CO poisoning symptoms include headaches, dizziness, nausea, and weakness, but these are so similar to flu symptoms that people often dismiss them or treat them with over-the-counter medications instead of investigating potential CO exposure. The key warning sign that should make you think CO instead of flu is when multiple household members are experiencing these symptoms simultaneously, especially if they improve when you leave the house.

Professional Gas Appliance Safety Inspection Process

Understanding what professional inspections actually involve helps you know what to expect and ensures you’re getting thorough service that actually protects your family. When I perform gas appliance safety checks, there’s a systematic process that goes way beyond just eyeballing your equipment and calling it good. The comprehensive assessment starts with visual inspection of all gas appliances, checking lines and fittings for any signs of damage, corrosion, or leakage. This isn’t just a quick glance – we’re looking for subtle changes in metal coloration, scoring on connections, or any evidence that joints have been disturbed or are deteriorating. Gas Safe registered engineers are trained to spot issues that homeowners typically miss because we know what failure patterns look like before they become emergencies. Testing includes gas pressure and flow verification to ensure your appliances are getting the right amount of fuel at the correct pressure. Too little pressure and appliances won’t operate efficiently; too much pressure creates safety risks and can damage internal components. We use calibrated instruments to measure these parameters because eyeballing gas flow just doesn’t cut it when safety is on the line. Functional testing of safety devices like Flame Failure Safety Devices and thermostats is where things get technical, but it’s absolutely critical for preventing CO incidents. These safety systems are designed to shut off gas flow if flames go out unexpectedly or if temperatures exceed safe parameters. If safety devices aren’t working properly, you could have gas flowing without combustion, which creates explosion risks