Appliance Noise Decoder: What Every Sound From Your Home Appliances Means (And When Burnaby Homeowners Should Worry)

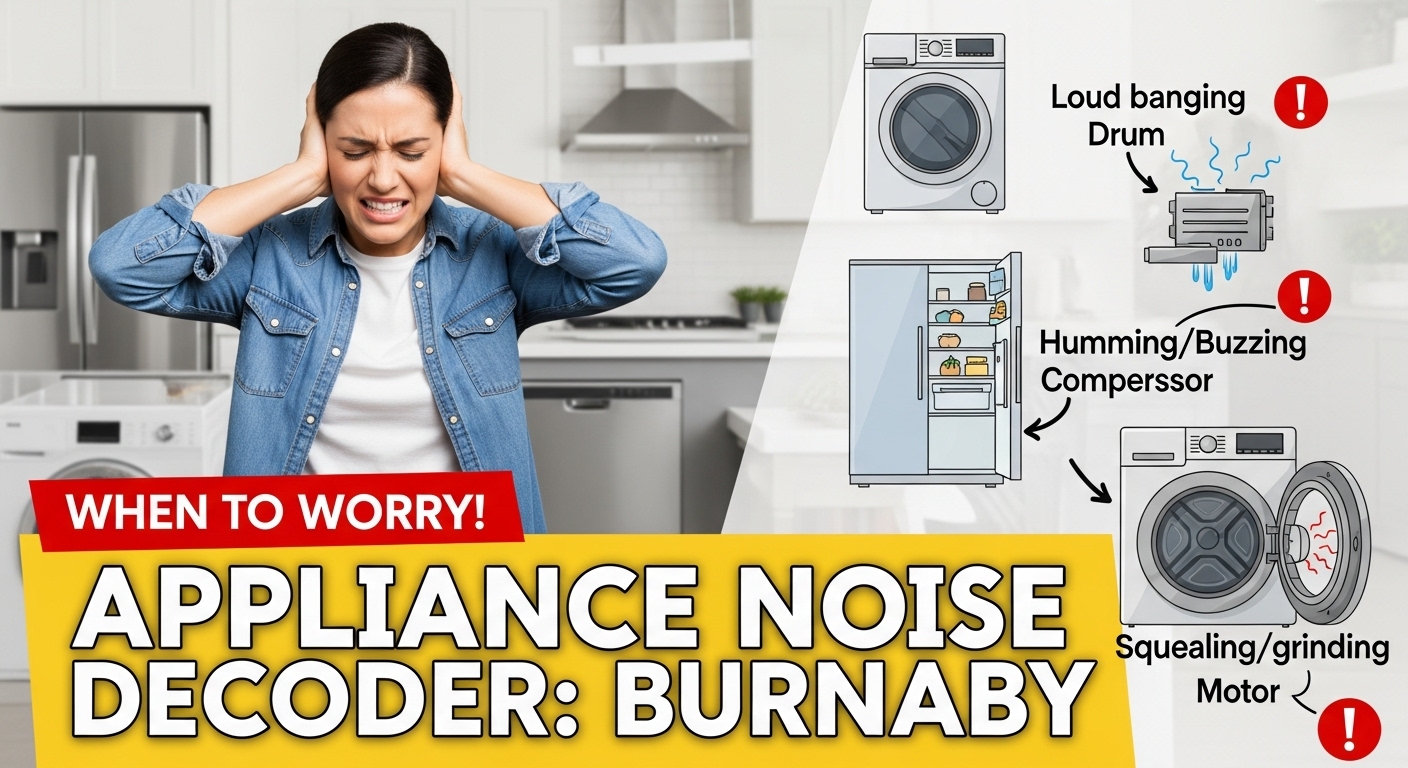

Tired of wondering if that mysterious grinding sound from your washing machine is normal or a sign of impending disaster? This comprehensive guide decodes every appliance noise you’ve ever questioned, revealing exactly when Burnaby homeowners should take action versus when they can relax and ignore those household sounds.

Your home appliances work tirelessly behind the scenes, keeping your food fresh, clothes clean, and dishes sparkling. But when these trusty machines start making unfamiliar sounds, it can feel like they’re speaking a language you don’t understand. That gentle refrigerator hum suddenly becomes a concerning buzz, or your dryer’s usual tumbling transforms into an alarming screech. Learning to decode these appliance sounds isn’t just about peace of mind – it’s about protecting your investment and ensuring your family’s safety.

Every appliance has its own acoustic signature, and understanding these patterns can save Burnaby homeowners hundreds or even thousands of dollars in premature replacements. The key lies in distinguishing between normal operational sounds and warning signals that demand immediate attention. When you know what to listen for, you can catch small problems before they snowball into major repairs or safety hazards.

The difference between a $100 service call and a $3,000 appliance replacement often comes down to recognizing these audio clues early. Whether it’s the subtle change in your refrigerator’s compressor cycle or the first signs of bearing wear in your washing machine, your appliances are constantly communicating their health status through sound.

- Normal appliance sounds indicate proper operation, while sudden changes in noise patterns signal potential problems requiring immediate attention

- Grinding, screeching, and persistent electrical buzzing are universal danger signals across all appliances that demand professional repair service

- Early noise diagnosis can prevent minor issues from escalating into major repairs, potentially saving Burnaby homeowners hundreds to thousands in replacement costs

- Certain appliance noises indicate fire hazards, with clothes dryers causing over 16,000 house fires annually due to lint accumulation and mechanical failures

- Seasonal factors in Burnaby’s climate can affect appliance noise levels and require adjusted maintenance schedules

Understanding Normal vs. Abnormal Appliance Sounds

Think of your appliances as having their own personalities, each with a unique voice that changes throughout their operational cycles. A well-maintained appliance operates with predictable, relatively quiet sounds during normal function. These baseline sounds become your reference point for detecting when something goes wrong. The refrigerator’s gentle hum, the dishwasher’s rhythmic swooshing, and the dryer’s steady tumbling all represent healthy appliance operation.

The challenge comes when these familiar sounds start changing. Sudden shifts in volume, pitch, or frequency often signal the beginning of mechanical problems. What might start as a slightly louder compressor hum can quickly escalate to a failing motor if left unchecked. Understanding these patterns helps you distinguish between temporary operational variations and genuine warning signs that require attention.

Modern appliances essentially use sound as their primary diagnostic tool, communicating their internal status through various audio cues. Normal operational sounds include startup clicks, cycle transitions, and motor engagement noises. However, unusual sounds serve as early warning systems, alerting you to developing problems before they cause complete system failures. This built-in diagnostic capability makes sound recognition one of the most valuable troubleshooting skills any homeowner can develop.

Environmental factors also play a significant role in appliance noise levels, particularly in Burnaby’s coastal climate. Higher humidity levels can amplify certain sounds or create additional vibrations as components expand and contract. Understanding how seasonal changes affect your appliances’ acoustic patterns helps you separate climate-related noise variations from genuine mechanical issues requiring professional attention.

Refrigerator and Freezer Noise Diagnosis

Your refrigerator works harder than almost any other appliance in your home, running continuously to maintain optimal food storage temperatures. This constant operation creates a variety of sounds that homeowners need to understand for proper maintenance and safety. The key to refrigerator noise diagnosis lies in recognizing the normal operational cycles and identifying when sounds indicate potential problems.

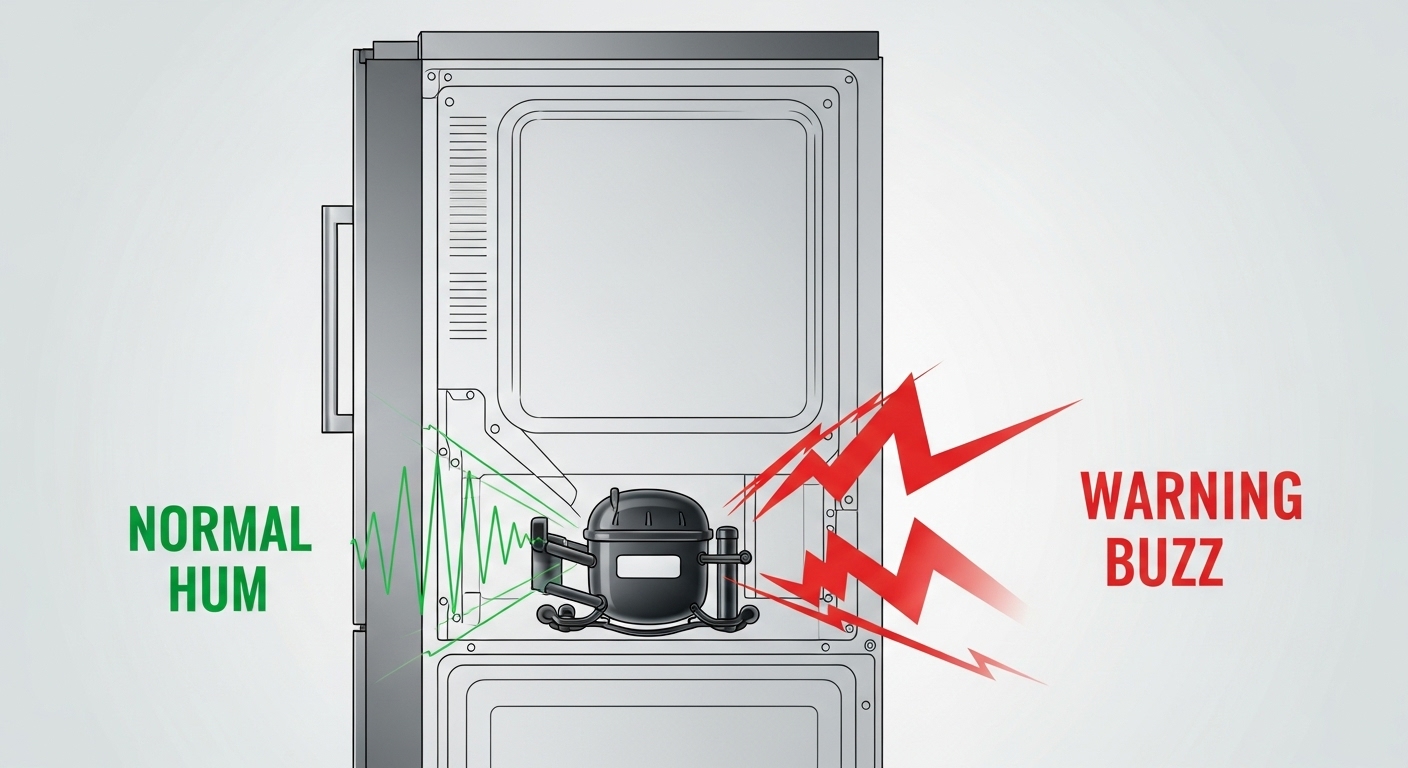

The compressor represents the heart of your refrigeration system, and its acoustic signature provides valuable diagnostic information. A healthy compressor produces a low, consistent hum during cooling cycles, typically running for 15-20 minutes before cycling off. However, when the compressor starts working harder than normal, perhaps due to dirty coils or inadequate ventilation, this hum becomes noticeably louder and more persistent. Understanding these compressor patterns helps homeowners identify when their refrigerator needs professional attention before costly failures occur.

Normal refrigerator operation includes several predictable sounds that shouldn’t cause concern. The defrost timer creates occasional clicking as it switches between cooling and defrost modes. Ice makers produce characteristic dropping and grinding sounds during ice production cycles. Refrigerant flowing through the cooling system creates gentle gurgling or bubbling sounds, particularly noticeable during startup and shutdown periods. These sounds represent normal system operation and don’t require intervention.

Warning signs that demand immediate attention include rapid, persistent clicking that could indicate a faulty start relay or compressor problems. Loud grinding noises often signal evaporator fan issues, possibly due to ice buildup or foreign object interference. Excessive rattling typically points to loose components or failing mounting hardware. Most concerning are electrical buzzing sounds accompanied by burning odors, which can indicate dangerous electrical problems requiring immediate professional service.

Temperature control problems often manifest through acoustic symptoms before affecting food storage. A compressor that runs constantly without cycling off suggests the system is working too hard to maintain temperature, possibly due to refrigerant leaks or failing components. Conversely, a compressor that clicks on and off rapidly might indicate electrical relay problems or low refrigerant levels. These patterns help homeowners identify cooling system issues before food spoilage becomes a problem.

Washing Machine and Dryer Sound Analysis

Laundry appliances provide some of the most dramatic examples of how sound patterns indicate mechanical health and safety conditions. These machines experience significant mechanical stress during operation, making them particularly susceptible to wear-related noise issues. Understanding washing machine and dryer sounds becomes crucial for preventing both costly repairs and dangerous safety situations, including fire hazards.

Washing machine noise patterns typically correlate with specific operational phases and load conditions. During the wash cycle, normal sounds include water filling, agitation motor operation, and drain pump activation. The spin cycle naturally produces higher noise levels due to high-speed drum rotation, but this should remain relatively consistent for similar load sizes. Banging or thumping during spin cycles usually indicates unbalanced loads, but persistent banging might signal broken drive belts or worn suspension components requiring professional repair.

Squealing or screeching sounds from washing machines almost always indicate worn or loose drive belts connecting the motor to the drum assembly. These belt issues can lead to much more expensive repairs if the belt completely breaks, potentially damaging the motor or transmission. Early intervention when squealing first appears typically involves simple belt adjustment or replacement, while delayed repairs often require major component replacements.

Dryer safety becomes particularly critical given the fire hazards associated with these appliances. Every year, over 16,000 house fires are caused by clothes dryers, with ignition mostly occurring when lint accumulation combines with overheating heating elements. Acoustic warning signs of potential fire hazards include unusual grinding during tumbling, which might indicate foreign objects near the heating element, or high-pitched squealing suggesting bearing failures that could allow excessive heat buildup.

Normal dryer operation produces predictable tumbling sounds as clothes move through the heated air circulation. However, several sound patterns indicate immediate safety concerns. Persistent grinding early in cycles often stems from debris caught in the drum seal or lint buildup around heating elements. Loud rattling might indicate loose heat shields or damaged exhaust components. Most critically, any burning smell accompanied by unusual sounds requires immediate shutdown and professional inspection to prevent fire hazards.

Drive system problems in both washers and dryers create distinctive sound signatures that help diagnose specific component failures. Motor capacitor problems typically manifest as humming without drum movement, while belt issues create rubber-to-metal squealing sounds. Bearing wear produces grinding noises that worsen over time, eventually leading to complete mechanical failure if not addressed promptly through professional repair services.

Kitchen Appliance Noise Troubleshooting

Kitchen appliances operate in unique environments that create specific acoustic challenges and safety considerations. These machines handle water, electricity, and often gas connections, making sound-based diagnostics particularly important for identifying potentially dangerous situations. From dishwashers managing high-pressure water systems to microwaves generating electromagnetic radiation, kitchen appliances require careful acoustic monitoring for both performance and safety reasons.

Dishwasher operation involves complex water circulation systems that create various normal sounds during different cycle phases. The wash cycle produces water swishing and spray